Despite its potential, bioprinting faces major challenges, including unintended polymerization and damage to surrounding bioinks caused by light exposure, which compromises the precision and viability of the printed structures.

These issues reduce the accuracy of fabricated tissues, limiting their applications in regenerative medicine, drug testing, and prosthetics. However, a breakthrough solution has emerged—photoinhibiting additives—which significantly enhance bioprinting precision and structural fidelity.

What is Photoinhibiting additives and How it Enhance Bioprinting

Photoinhibiting additives are specialized chemical compounds used in light-based 3D bioprinting to control polymerization and improve printing accuracy. These additives absorb or regulate the light exposure during the printing process, preventing unwanted solidification and ensuring high-fidelity, precise structures.

How Photoinhibiting Additives Enhance Bioprinting

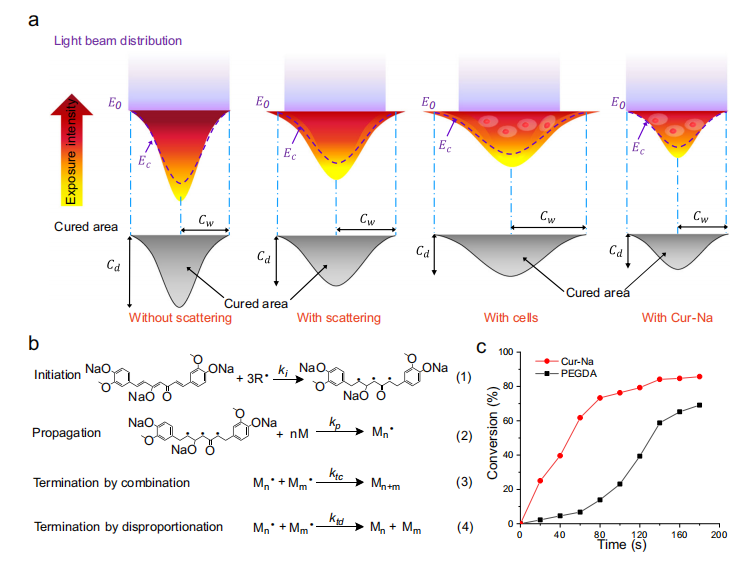

- Minimizing Light Scattering: Photoinhibitors, such as Curcumin-Na, suppress unwanted polymerization by absorbing excess light, preventing off-target curing.

- Preserving Cell Viability: The controlled polymerization process ensures that embedded cells maintain their structure and function.

- Improving Printing Resolution: Using photoinhibitors, Digital Light Processing (DLP) bioprinting achieves better spatial resolution (~1.2-2.1 pixels) and geometric accuracy (<5% error).

- Enhancing Complex Structure Fabrication: Enables the creation of intricate structures like multi-vascular networks and cell-laden scaffolds.

Using Curcumin-NA as a Photoinhibition agent:

Photoinhibiting approach that promotes the fabrication resolution and pattern fidelity of DLP bioprinting by addressing the light scattering problem through a newly developed photoinhibiting additive (curcumin-Na (Cur-Na)). Curcumin-Na was synthesised by chemically modifying curcumin using sodium bicarbonate. With this method, the printing resolution and pattern fidelity are significantly enhanced, and various complex 3D structures with multiscale features (particularly 3D cellularised scaffolds) can be fabricated all at once without re-tuning the printing parameters

This biocompatible approach significantly improves the printing resolution (~1.2 - ~2.1 pixels depending on swelling) and shape fidelity (geometric error less than 5%), while minimising the costly trial-and-error procedures.

How BMF’s Micro 3D Printing Enhances Bioprinting

BMF’s NanoArch S140 micro 3D printer offers:

- Unmatched precision (2µm resolution) for creating ultra-complex biological structures.

- Rapid prototyping capabilities, enabling researchers to develop new bioinks and tissue models.

- Advanced Digital Light Processing (DLP) technology, optimized for high-fidelity tissue engineering.

By incorporating photoinhibiting additives, BMF’s micro 3D printing technology is setting new standards for bioprinting precision, making high-fidelity tissue engineering more feasible than ever.

Interested in high-resolution bioprinting?

Contact us for a personalized meeting