Glass manufacturing has long faced challenges such as high production costs, design constraints, and material limitations. Meanwhile, the demand for high-precision glass components in micro-optics, microfluidics, and medical devices continues to grow.

Recent advancements in Boston Micro Fabrication (BMF) 3D printing technology are overcoming these obstacles, enabling the production of high-resolution, intricate glass structures for industries such as optics, photonics, and healthcare.

How BMF Micro 3D Printing Solves Glass Manufacturing Challenges

In a groundbreaking study published in Nature Communications, researchers showcased the capabilities of BMF printers in producing fused silica glass with intricate sub-micron features, demonstrating their potential in advanced applications such as micro-optics, microfluidics, mechanical metamaterials, and engineered surfaces. This research highlights how BMF's technology can lead to groundbreaking developments in product design and functionality.

BMF’s innovative One-Photon Micro-Stereolithography (OμSL) technology enables the production of high-quality, transparent glass components with exceptional precision, meeting the stringent requirements of advanced applications across industries such as optics, photonics, and microfluidics.

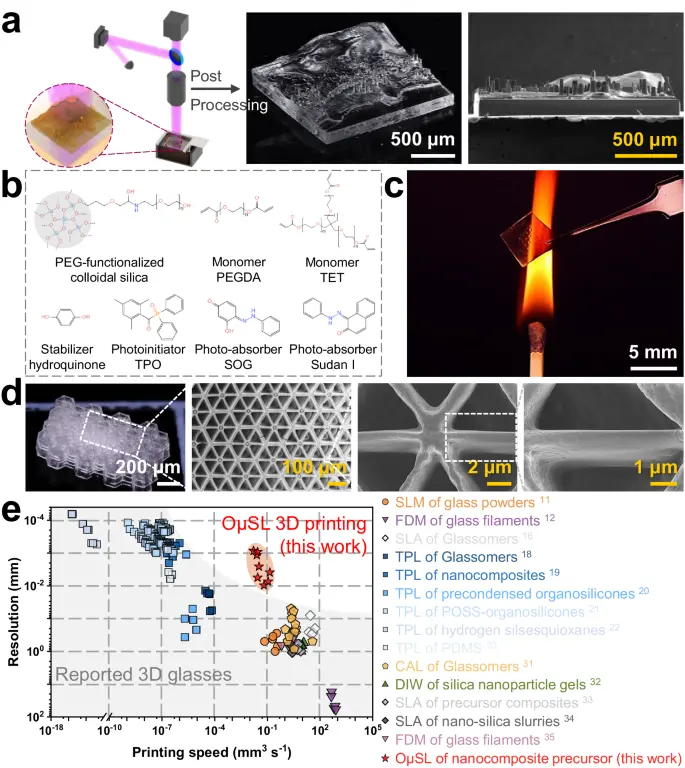

a Illustration of OμSL configuration and its forming process; bottom left inset: schematic of the 3D miniature Hong Kong dioramas structure in printing; and optical & electron microscopic images of the 3D-printed fused silica glass miniature Hong Kong dioramas microstructure. b Chemical structures of the nanocomposite precursor. PEG-functionalized colloidal silica as the silica source, PEGDA and TET as the PEG-based bifunctional and trifunctional monomer, hydroquinone as the stabilizer, Irgacure TPO as the photoinitiator, and SOG and Sudan I as the photo-absorbers. c High-temperature stability demonstration of an OμSL 3D-printed transparent fused silica glass MLA at hundreds of degrees. d Optical & electron microscopic images of the 4 × 6 honeycomb structure with slender threads centrally suspended. e Plot of the finest resolution against the maximum printing speed of the 3D-printed transparent fused silica glass in our work, together with the data of other reported 3D-printed transparent fused silica glass for comparison.

|

Why OµSL is a Breakthrough in Fused Silica Glass Manufacturing

Sub-Micron Resolution:

Achieves a voxel size as small as 0.8 × 0.8 × 0.5 µm, enabling intricate designs.

High Material Purity:

Produces stoichiometrically pure silica, ensuring optical clarity and structural integrity.

Versatile Applications:

Ideal for optical lenses, photonic circuits, and precision medical instruments.

Scalability & Cost Reduction:

Eliminates the need for complex molding processes, reducing production costs and increasing design flexibility.

BMF 3D Printing Solutions

Ultra-High Precision – Achieves sub-micron features that conventional techniques struggle to replicate.

Cost Efficiency – Reduces reliance on expensive molds and tooling, significantly cutting production costs.

Material Versatility – Enables the use of high-quality fused silica, perfect for advanced optical components.

Scalability & Customization – Allows manufacturers to rapidly prototype and scale production without the long lead times of traditional methods.

BMF’s OµSL technology is pushing the boundaries of fused silica glass manufacturing, making ultra-precise, high-purity glass components more accessible

Ready to upgrade your glass manufacturing process?

Contact us for a personalized meeting